| Back OpEd News | |||||||

|

Original Content at https://www.opednews.com/articles/The-EPA-WaterSense-Shower-Water-Quality_Water-Supply-240616-90.html (Note: You can view every article as one long page if you sign up as an Advocate Member, or higher). |

|||||||

June 16, 2024

The EPA WaterSense Shower Hoax Versus Water Main Breaks

By Robert A. Leishear, PhD, PE, ASME Fellow

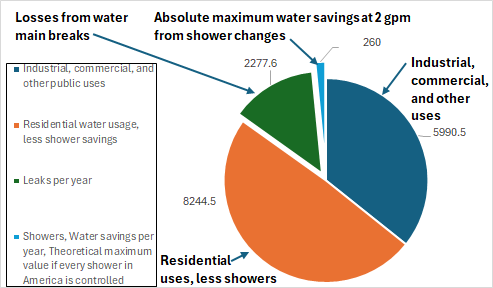

The EPA claims that the U.S. can save 260 billion gallons of water annually per year, yet the EPA permits 2.278 trillion gallons of water to be lost every year, where water-main breaks are the primary cause of these leaks. There are presently 60 billion dollars per year in over-profits to support a monumental water-main repair and research industry. Stop the water-main breaks, stop the profit gouging, and save our water.

::::::::

The EPA claims that the U.S. can save 260 billion gallons of water annually per year, yet the EPA permits 2.278 trillion gallons of water to be lost every year, where water-main breaks are the primary cause of these leaks. There are presently 60 billion dollars per year in over-profits to support a monumental water-main repair and research industry. Stop the water-main breaks, stop the profit gouging, and save our water supply.

The Facts

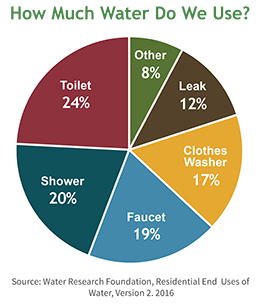

- Neglecting storage tank overflows, approximately 16% of our provided water supply is lost to leaks (Figure 1, "Trillions of gallons leak from aging drinking water systems, further stressing shrinking US cities", click here). Other water loss estimates vary from 20% to 30% of our water supply for these nonrevenue water losses.

- Annual U.S. water use equals 14.235 trillion gallons per year (Figure 2, 39 billion gallons per day).

- Lost water from water main breaks therefore equals 6.24 billion gallons per day (2.278 trillion gallons per year).

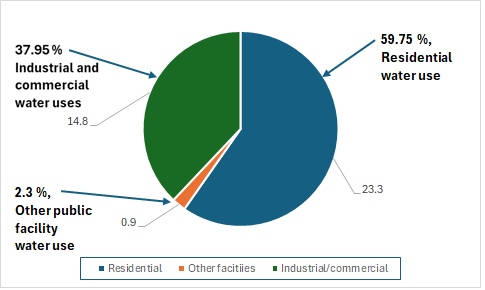

- Approximately 59.75% of public supply water use is for residential usage (8.504 trillion gallons per year, Figure 3).

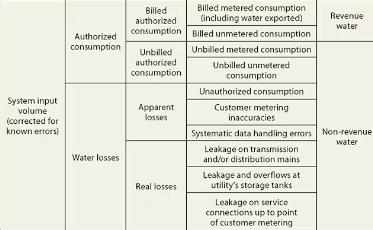

- Approximately 20% of household water is used for showers (1.65 trillion gallons per year, Figure 4).

- The EPA requires that homes limit shower installations to 2.0 gpm (gallons per minute), which yields a maximum water savings of 260 billion gallons per year in the U.S., according to the EPA ("Shower Better" Click Here).

- California has reduced this shower limit to 1.8 gpm ("The Complete Guide to Showerhead Flow Rates in California", click here).

Figure 1. Water losses from water mains ('Non-Revenue Water Loss: Its Causes and Cures').

(Image by International Water Association) Details DMCA

Figure 2. Total water use in the U.S ('Summary of Estimated Water Use in the United States in 2015').

(Image by USGS) Details DMCA

Figure 3. Public water supply ('Estimated Use of Water in the United States in 2015', units = billions of gallons).

(Image by Adapted from USGS) Details DMCA

The Facts Are Clear

Our water supply is in jeopardy ("Why is America running out of water?", click here). Not only do global warming droughts decrease available water for our use, but the stored underground water - that supplies an important part of our water supply - decreases due to our use (Figure 5 and "The Global Warming Fallacy, Polar Warming, Energy Use, and Continental Shifts"). Also, note that more than 264 quadrillion gallons have been permanently pumped out of U.S. underground aquifers, which is sufficient to supply all U.S. water uses for 2.25 years or 31.1 years to supply all residential water uses.

Even though our water supply is in jeopardy, the EPA blames the wrong problem. A hoax is defined by Merriam-Webster as 'something false passed off or accepted as genuine'. Constituting a hoax, the EPA blames us for using too much water when we take showers, which does not fix the overwhelming water-main-break problem. 'Money before the lives of citizens is government policy and priority.' 'Our lives and our environment are at risk, where industrial profits overrule government actions that could stop disasters' ("Book Publisher Wanted for a New Book, 'Industrial Murder for Profit'").

Figure 5. Decreases in available U.S. water storage due to our use of underground aquifers. ('Groundwater Decline and Depletion', 1 cubic kilometer = 264 trillion gallons).

(Image by USGS) Details DMCA

What You Need to Know About the Facts

If every shower in the entire USA is retrofitted with new shower fixtures to reduce water-flow rates, the water savings would only be 11.4% of the savings that could be achieved by stopping our water-main breaks, or 1.83% of total U.S. water usage (Figure 6). If the California shower water change from 2 gpm to 1.8 gpm is implemented throughout the entire U.S., the water savings would be even less at 1.14% of water leaks, or 0.37% of the total U.S water usage. More importantly, there is no chance that every U.S. shower will be changed - ask your neighbors if they are going to pay to retrofit their showers.

Added benefits from stopping our water-main breaks follow.

- Reductions in illness and deaths ("The CDC Blames Workers for Food Poisonings to Cover-up Their Incompetence", "The CDC Should Stop Drinking-Water Dangers - Stop E. Coli and Listeria Disease Outbreaks and Lead and Copper Poisonings!").

- Fish kills can be stopped when chlorinated water from breaks contaminates our streams.

- An incoming trillion dollars in water-main breaks can be stopped over the next 25 years. ("Water-Main Breaks in Mississippi and Across U.S. Can Be Stopped", click here).

- The current water repair cost estimate from AWWA Journal publications is 60 billion dollars per year. This cost can be drastically cut, and could even be nearly eliminated.

Nearly all water-main breaks are preventable ("Water Hammer Causes Water-Main Breaks", click here).

Figure 6. Water main break water losses versus water savings from shower flow rate changes to 2 gpm (units = billions of gallons).

(Image by Leishear Engineering, LLC) Details DMCA

What Must Be Done With The Facts

Water-main breaks can be stopped ("The Winter Flood of Water-Main Breaks Can Be Stopped - Water-Main Breaks in Jackson and Every Other City Can be Stopped"). Even so, there is amazing resistance to peer-reviewed research findings that can stop our water-main breaks ("AWWA Censorship: Staunch Resistance to New Ideas Destroys our Water System and Risks Our Lives"). Such resistance to new technology unnecessarily costs our lives, our water supplies, and our environment.

We do not know the future costs of lost water supplies to failing health and loss of life. However, ignoring these potential costs until they are due is the dangerous policy that we now pursue.

Addendum

The following message was forwarded o the EPA, the AWWA and the Governor of California when this article was published. My one-man fight against government organizations and professional societies to protect our lives and environment surges in full force.

Responses were not received - as expected.The EPA WaterSense Shower Hoax Versus Water-Main Breaks, OpEd News

Dear Sirs;

Although regulating the flow of water in showers provides some negligible relief to water shortages, this approach lacks a sound technical background, results in misspent taxes, and incurs preventable risks to our health, the environment, and the water supplies in our country. As mentioned in a new Op Ed, water savings from preventable water main breaks dwarf the water savings from changes to how we take showers. If you stop water-main breaks, tremendous water savings will be realized. Please provide comments.

(Article changed on Jun 17, 2024 at 11:58 AM EDT)

Authors Website: http://www.leishearengineeringllc.com

Authors Bio:

Robert A. Leishear, PhD, P.E., PMP, ASME Fellow, Who's Who in America Top Engineer, Who's Who Millennium Magazine cover story, NACE Senior Corrosion Technologist, NACE Senior Internal Piping Corrosion Technologist, ANSYS Expert, AMPP Certified Protective Coatings Inspector, NACE Cathodic Protection Tester, Structural Steel Worker, Welder, Carpenter, and Journeyman Sheet Metal Mechanic, is a Consulting Engineer for Leishear Engineering, LLC, and worked as a Lead Research Engineer (Principal Researcher) for the U.S. Department of Energy's (DOE) Savannah River National Laboratory (IQ = 161). He has also worked as a design engineer, test engineer, and plant engineer in nuclear waste facilities and nuclear fuel reprocessing facilities.

Additionally, Dr. Leishear worked as a lead electronic packaging design engineer for military aircraft and missile systems. In this position, he designed the first wireless aircraft radar system, and he patented an electromagnetic interference mechanism to ensure that aircraft radar computer systems remained operational for second strike capabilities in the event of nuclear war, where this mechanism was installed on all personal computers and printers for decades.

Dr. Leishear has written more than 190 technical publications on water hammer, nuclear plant explosions, and other research. Publications by the American Society of Mechanical Engineers include two water hammer and piping design books and Honors Journal publications.

Dr. Leishear received the Mensa, Copper Black Award for Creative Intelligence for his research on nuclear power plant explosions and petroleum industry explosions. He was appointed as an ASME Fellow for his research on water hammers, which are directly applicable to industrial explosions.

Dr. Leishear earned a B.S. in Mechanical Engineering from Johns Hopkins University, and at the University of South Carolina, he earned M.S. and PhD degrees in Mechanical Engineering, and also earned a Master of Engineering degree in Nuclear Engineering. For these degrees he studied, fracture mechanics, water hammer, fluid mechanics, mass transfer, gas dynamics, materials science, fatigue cracking, advanced thermodynamics, reactor thermal hydraulics, risk analysis, engineering law, reactor design, reactor physics, radiation shielding, reactor materials science, nuclear fuel cycles, reactor water chemistry, nuclear material safeguards, finite element analysis, structural vibrations, machinery vibrations, HVAC design, combustion, explosions, and structural analysis.

He has also extensively studied nuclear reactor physics, nuclear reactor thermal/fluid modeling, and nuclear reactor fuel design through Oak Ridge National Laboratories, the University of Illinois, the University of Barcelona, and the U.S. NRC; 12 corrosion courses through the Association for Materials Protection and Performance (AMPP/NACE); water treatment classes through the American Water Works Association; 7 combustion courses through the Combustion Institute at Princeton University and CERFACS; 20 Fluent and Ansys computer modeling courses; plus International Nuclear Law at the University of Singapore and International Radiological Protection at Stockholm University in Sweden through the OECD, Nuclear Energy Agency.

He also completed two years of full-time training at the DOE, Savannah River Site to understand infrastructure, diesel engines, pumps, compressors, fans, heat exchangers, evaporators, steam systems, air and nitrogen systems, mixing, instrumentation, calibrations, machinery design, fire protection systems, safety analysis, emergency response, radiation worker, electrical worker, first aid, explosion risks, plus 17 ASME courses on pressure vessel design, inspection, and piping design. At SRS, he also studied nuclear industry processes, which included chemistry, radiochemistry, and physics for nuclear waste disposal and nuclear fuel reprocessing. He was also trained for 6 weeks at SRS as an HVAC, electrical, and electronics systems mechanic.

Prior to his academic education, Bob Leishear earned his indenture papers through a four-year sheet metal apprenticeship, and he attended six months of training to learn to weld, build steel plate construction, and cut steel with an acetylene torch.